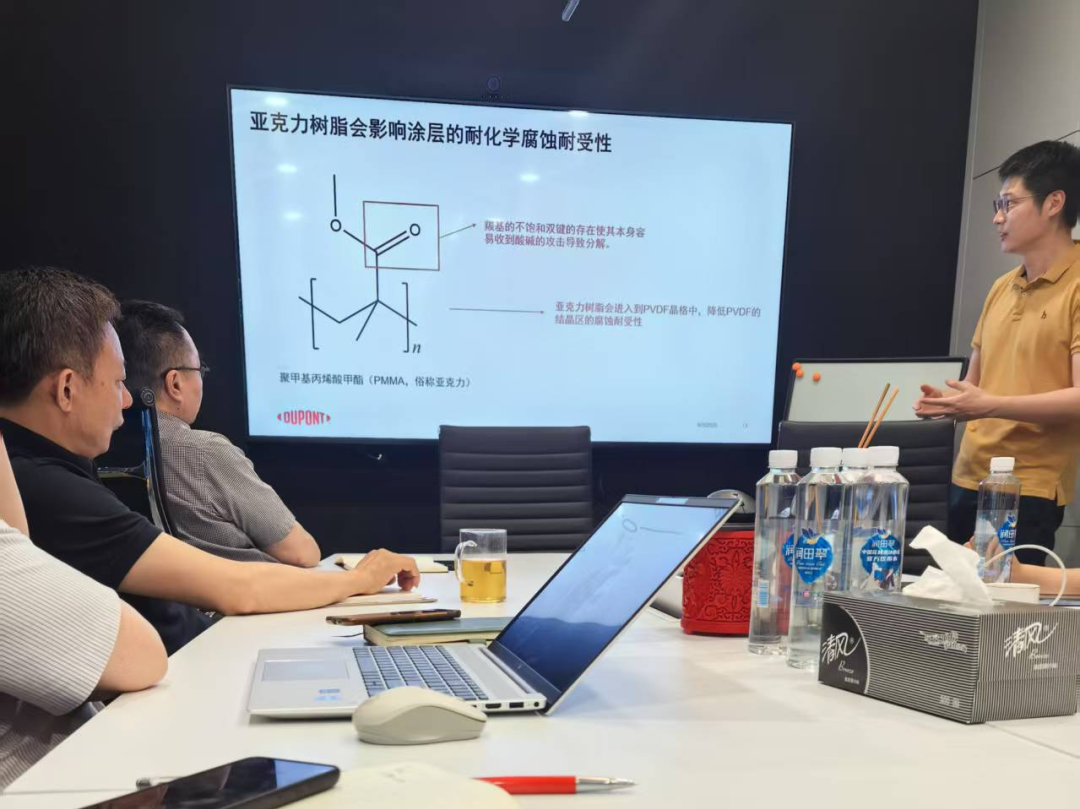

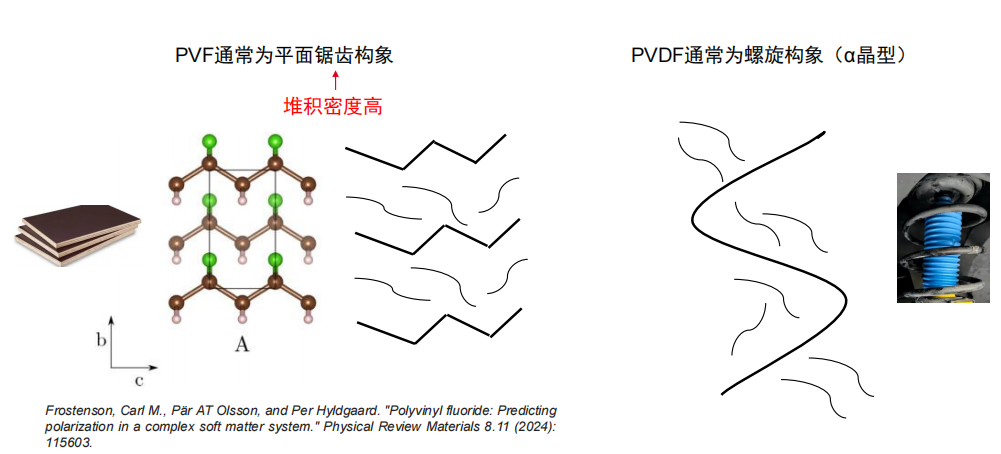

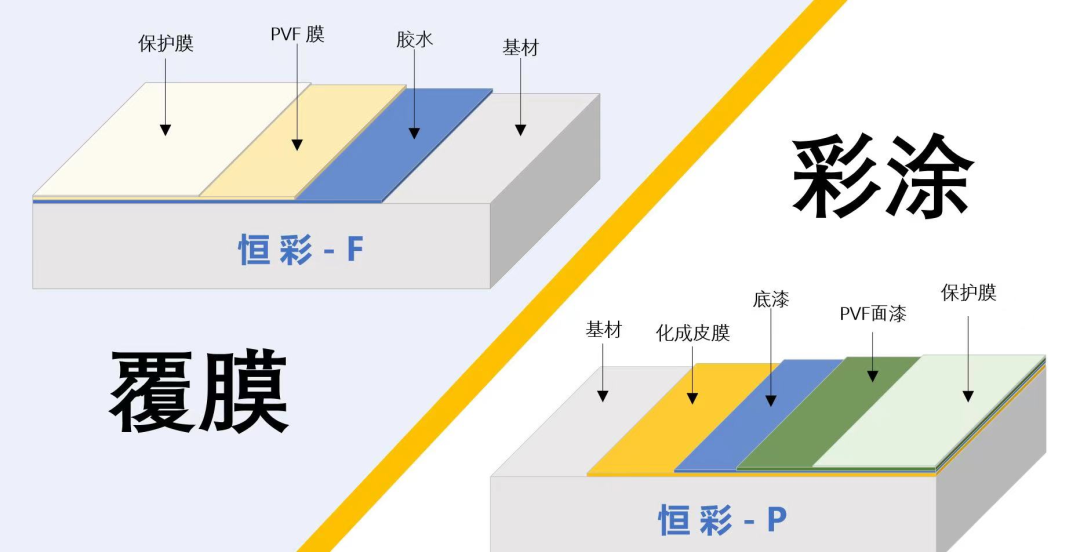

This exchange meeting has equipped the employees with a clearer, more comprehensive and in-depth knowledge of PVF and PVDF. All participants expressed that this training has greatly enriched their knowledge reserves, laying a solid foundation for the more accurate selection and application of DuPontTM Tedlar® products in future work. Zhang Wei shared, "After participating in the DuPontTM Tedlar® PVF Product Exchange Meeting, I have gained a deeper understanding of the weather resistance, chemical resistance, and long-term reliability of PVF materials, and realized that DuPontTM Tedlar® products hold enormous application potential in the power, petrochemical, and high-end construction sectors. In the future, we can strengthen product awareness through cooperation with design institutes, general contractors and end customers. Meanwhile, by leveraging project-based promotion, we will accurately explore segmented markets and drive the implementation of practical applications.